Glass Washing Machine After Screen Printing

Brand Junya

Product origin China

Delivery time 30 days

Supply capacity 50 sets/month

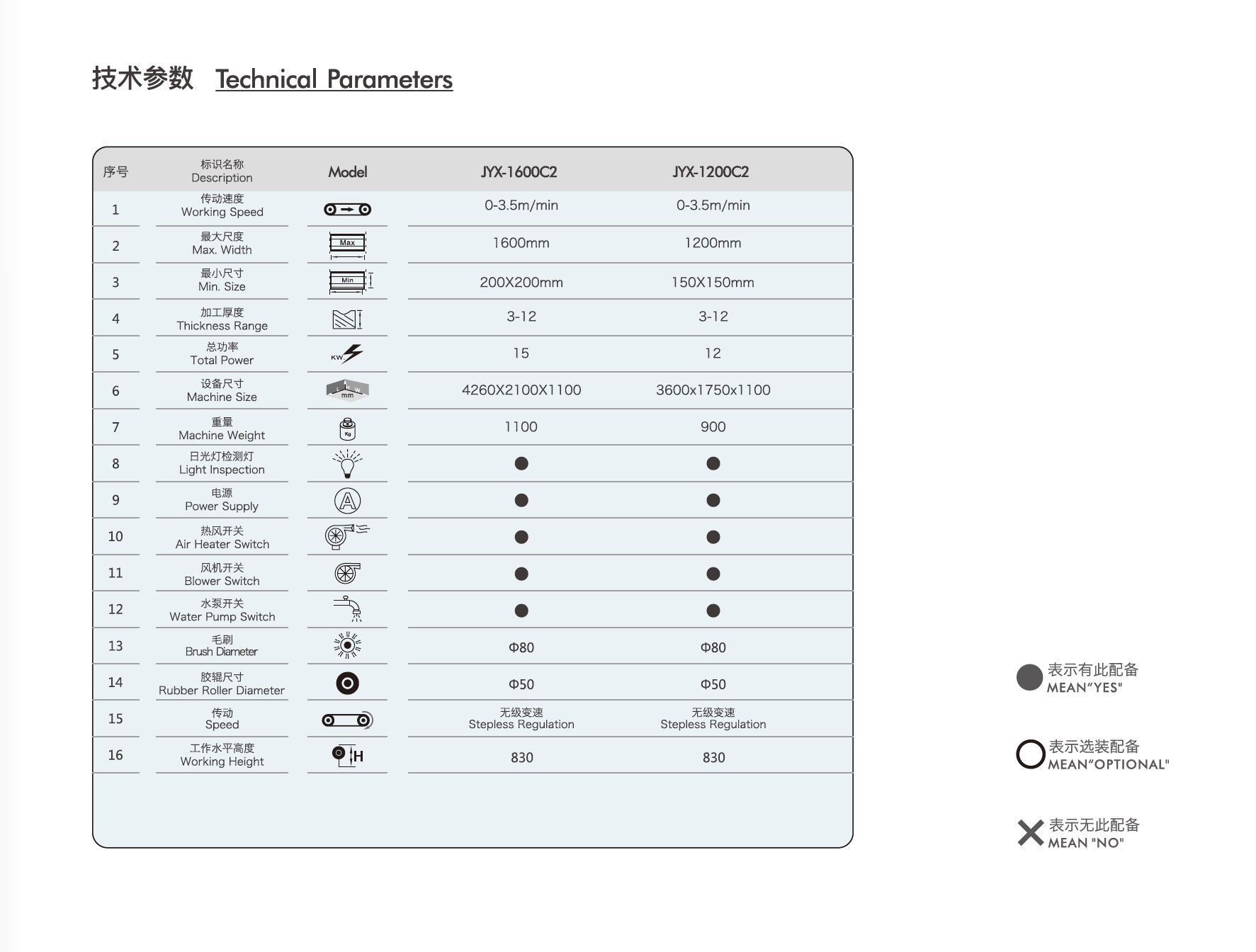

JYX-1600C2 GLASS WASHING MACHINE

The machine is good quality industrial glass washer,horizontal glass washing machine,screen print machine glass washer,glass equipment,and glass machining.

1. Horizontal glass washing machine is for washing and drying flat glass, which is applied for edged glass, glass before packing, glass before and after screen printing.

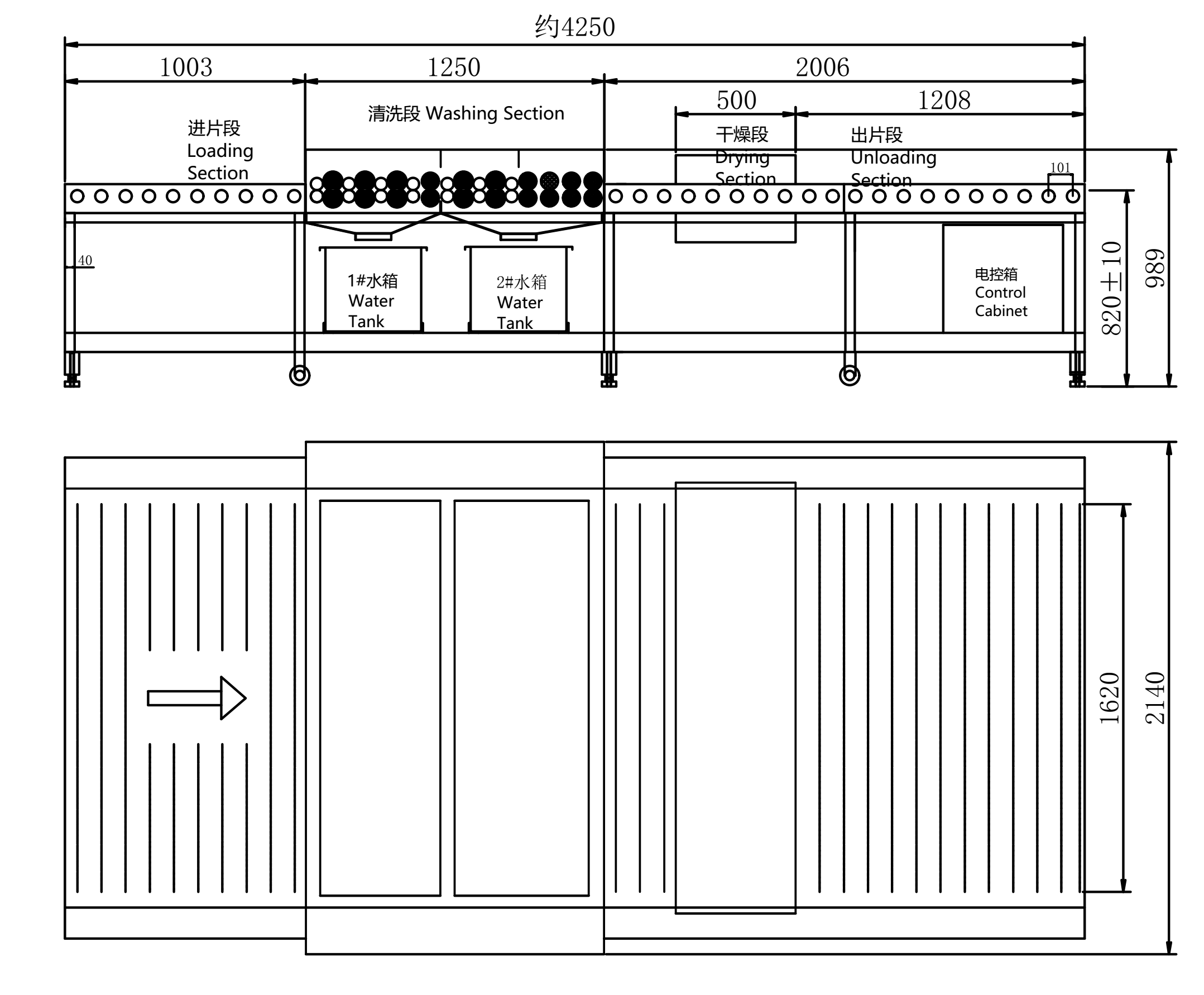

2. The horizontal glass washing machine mainly consists of loading section, washing section, drying section and unloading section.

3. Main drive is chain drive and stepless speed regulation

4. The horizontal glass washing machine is designed as two-step washing and equipped with two water tanks and high pressure pump.

5. The machine has five pairs of brushes and four pairs of sponge rollers.

Download

Structure Features

1.Horizontal glass washing machine is for washing and drying flat glass, which is applied for edged glass, glass before packing, glass before and after screen printing.

2.The machine mainly consists of loading section, washing section, drying section and unloading section.

3.Main drive is chain drive,speedless speed adjustment.

4.All protective covers, metal panels are made of stainless-steel material.

5.Water tanks are welded with SS material, and has filtering mesh.

6.Transmitting rubber rollers of the machine use top-grade nitrile rubber (Full cover of vulcanized rubber).

7.The machine has 2 stage washing with 2 water tanks and high-pressure water pump.

8.The machine has five pairs of brushes, four pairs of sponge rollers and two water tanks.

9.The machine has wide heating section (500mm)with centrifugal fan.

10.All bearings on the machines are customized to avoid problem of grinding roller shaft and change bearing frequently.The machine has separated aluminum frame for sponge roller changing convenience.

11.Working Environment: ordinary workshops or dust-free workshops

12.Machine noise level: less than 85DB; Measuring Method: test at 1m distance from loading and unloading section.

13.Safety certificate standard: 3C standard.