Maintenance of Glass Washing Machines: JUNYA Helps a Turkish Factory Set an Exemplary Model

In the highly competitive glass manufacturing industry, product quality and production efficiency are the keys for an enterprise to establish itself. As an important part of the production process, the maintenance level of glass washing machines directly affects the overall benefits of the enterprise. Recently, during the visit to a customer's factory in Turkey by the JUNYA team, they witnessed the excellent practices of the factory in maintaining glass washing machines, providing a highly valuable example for the whole industry.

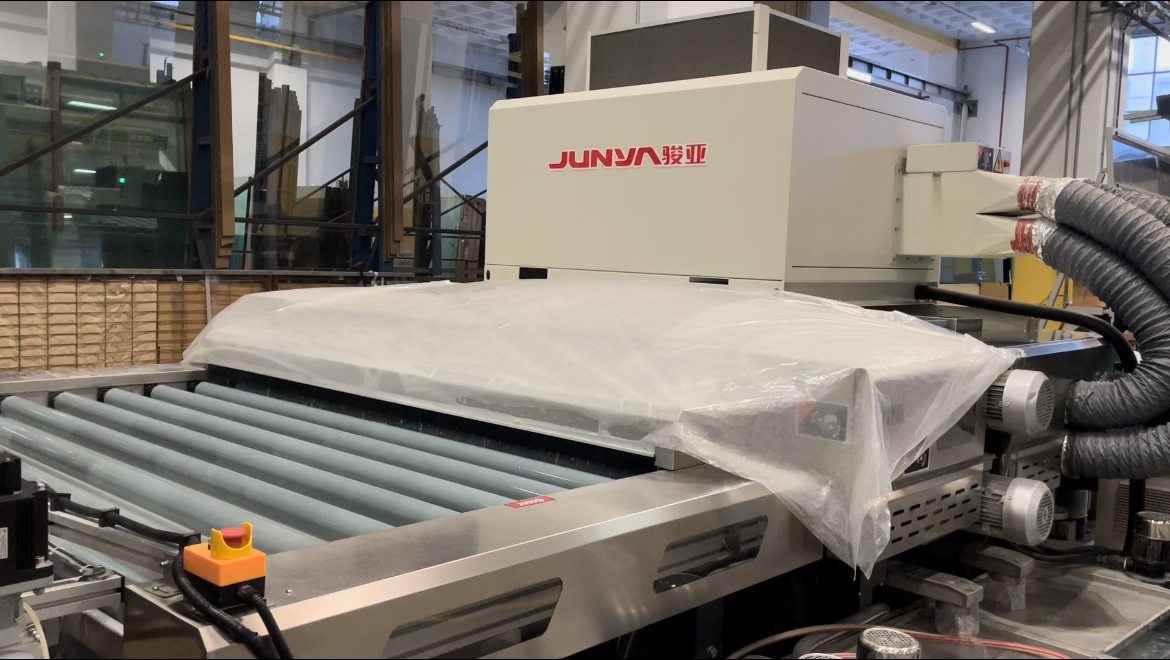

This Turkish glass manufacturing factory is large in scale. One of its core production lines has introduced a glass washing machine carefully crafted by JUNYA. Since it was put into operation, relying on JUNYA's advanced design concepts and superb manufacturing techniques, this washing machine has quickly become the "mainstay" of the production line. It stably and efficiently processes each piece of glass, providing clean and flawless basic materials for subsequent processing steps, effectively ensuring the coherence and high efficiency of the entire production process.

The factory management deeply recognizes the importance of equipment maintenance. To this end, they have assembled a maintenance team with extremely high professional proficiency and formulated detailed and rigorous job responsibilities and operation specifications. After the completion of daily production tasks, when the hustle and bustle of the production line gradually subsides, the maintenance personnel, like highly skilled craftsmen, embark on a meticulous care journey for the glass washing machine.

They will first use professional cleaning tools to carefully clean up various types of residual impurities on the surface of the machine body. Glass debris, water stains, and other dirt are all within the scope of their cleaning. If these impurities remain attached for a long time, they may corrode the components of the machine body, affect the heat dissipation performance, reduce the neatness of the appearance, and even enter the internal precision structures along with the vibration of the machine, causing wear and failure. The maintenance personnel patiently and meticulously wipe every corner to ensure that the machine body is as clean as new, creating a favorable external environment for the stable operation of the equipment.

Immediately afterwards, they focus their attention on the transmission system of the washing machine. The conveyor belt, as the key carrier for glass transmission, its condition is directly related to production safety and product quality. With their sharp observational skills and professional techniques, the maintenance personnel carefully check whether the belt has any signs of loosening, wear, or deviation. Once any abnormality is detected, they will promptly take precise adjustment measures or replace the belt in a timely manner to ensure that the glass can be transmitted smoothly and accurately during the cleaning process, avoiding situations such as getting stuck, slipping, or breaking.

The water spraying system is also a top priority in the maintenance work. The nozzles, as the core components of the water spraying system, whether they are unobstructed directly determines the cleaning effect of the glass. The maintenance personnel will check each nozzle one by one and use fine tools to clean up the tiny impurities that may clog the nozzles. These impurities may come from sediments in the water, glass debris, or dust in the air. Only by ensuring that the nozzles are unobstructed, the water spraying is uniform, and the pressure is stable can the glass surface reach the ideal cleanliness standard, laying a solid foundation for subsequent processing steps.

In the lubrication maintenance stage, the maintenance personnel always take the maintenance manual provided by JUNYA as their guide. They are well aware that regularly adding an appropriate amount and suitable lubricant to each transmission component is the key to prolonging the service life of the machine and reducing energy consumption. For key parts such as bearings and gears, they select high-quality lubricating oil and adopt a scientific and reasonable lubrication method to ensure that the lubricant is evenly distributed on each friction surface. Through such meticulous care, the transmission system of the glass washing machine operates more smoothly, the noise is significantly reduced, and the equipment failure rate is greatly reduced.

In addition, the inspection and maintenance of the electrical system are also not slackened. The maintenance personnel carefully examine the intricate lines to check whether there are any signs of damage or aging, and whether the terminal blocks are firm. Damaged lines may cause short circuits, leading to serious safety accidents such as electrical fires; aged lines may affect the stability of electrical signal transmission, thereby reducing the control accuracy and operation reliability of the machine. They promptly tighten the loose terminal blocks, replace the aged or damaged wires, and test the performance of the electrical components to ensure the safe and stable operation of the electrical system, providing a solid power guarantee for the normal operation of the glass washing machine.

Thanks to the daily, meticulous and professional maintenance work, the JUNYA glass washing machine in this Turkish factory has always been kept in the best operating state. The downtime due to failures has been minimized, and the production efficiency has experienced a qualitative leap. Problems such as production delays and output reductions that might have been caused by equipment failures no longer exist. The production line can operate continuously and stably, continuously producing high-quality glass products. Meanwhile, the stable cleaning quality provides strong support for subsequent processes such as coating, tempering, and cutting, effectively enhancing the quality and quality stability of the entire product.

In the current context where the glass manufacturing industry is facing challenges such as fluctuations in raw material prices, changing market demands, and fierce competition among peers, the maintenance work of glass washing machines is becoming increasingly strategically important. As demonstrated by the successful example of this Turkish factory, only by equipping professional maintenance personnel, establishing a complete maintenance system and strictly implementing it can an enterprise fully tap the potential efficiency of the equipment, reduce the high costs caused by failure repairs, including the cost of replacing parts, the labor cost of maintenance personnel, and the indirect losses caused by production stagnation. At the same time, this also helps to improve product quality and production efficiency, enhancing the core competitiveness of the enterprise in the market.

Other glass manufacturing enterprises should take this Turkish factory as an example, deeply understand the important value of equipment maintenance, and actively strengthen the maintenance of glass washing machines and other production equipment. By learning from advanced experiences and continuously improving their own equipment maintenance systems, the entire glass manufacturing industry is expected to achieve healthy and sustainable development. This will not only lay a solid foundation for the long-term development of individual enterprises but also promote the entire industry to take new steps in terms of technological innovation, product quality improvement, and market expansion, shining more brightly in the global glass manufacturing field.